This post is sponsored by The Home Depot. I have been compensated for my time and provided with product. All ideas and opinions are my own. This post contains some affiliate links for your convenience. Click here to read my full disclosure policy.

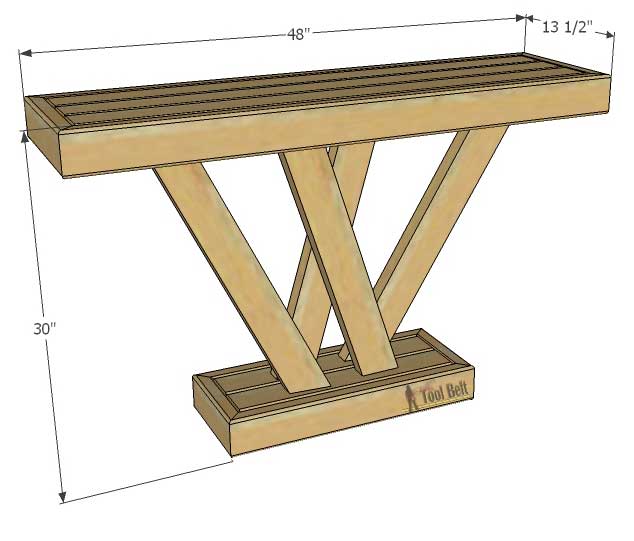

Remodelaholic put out the call and I thought it would be fun to participate in her structural lumber feature week called 2×4 and more. A while back I saw this Modera style console table and wanted to try those funky legs. It was the perfect piece to build out of all 2×4’s and easy too.

What do you think of that style? I think the console table legs could stand to be a little chunkier, but no matter what angle you look, they look different.

How to Build a 2×4 Console Table

Materials

- 6 – 2″ x 4″ x 8′ studs (actual size 1 1/2″ x 3 1/2″)

- 1 – corner brace (4 pack) – painted with ORB spray paint, optional

- stain – golden oak and kona

- Most of the finishing supplies I had left over from other projects, the wood and braces totaled to about $25.

Tools

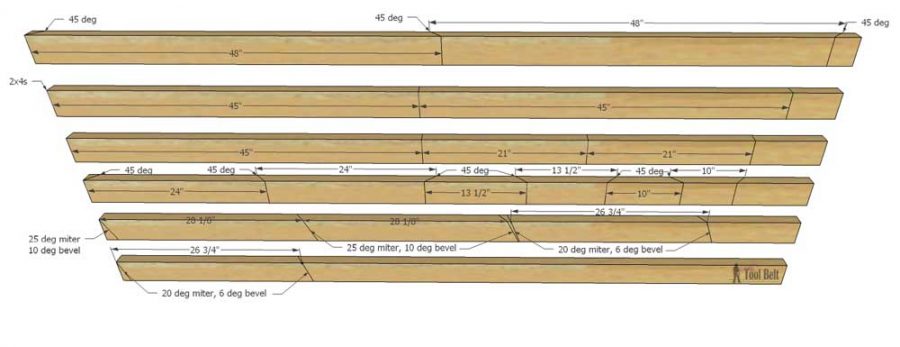

Cut list

- 2 – 1 1/2″ x 3 1/2″ x 48″ with 45 deg bevel cuts on each end facing each other (cut to fit)

- 3 – 1 1/2″ x 3 1/2″ x 45″

- 2 – 1 1/2″ x 3 1/2″ x 21″

- 2 – 1 1/2″ x 3 1/2″ x 24″ with 45 deg bevel cuts on each end facing each other (cut to fit)

- 2 – 1 1/2″ x 3 1/2″ x 13 1/2″ with 45 deg bevel cuts on each end facing each other (cut to fit)

- 2 – 1 1/2″ x 3 1/2″ x 10″ with 45 deg bevel cuts on each end facing each other (cut to fit)

- 2 – 1 1/2″ x 3 1/2″ x 28 1/8″ with a 25 deg miter/10 deg bevel cut on each end facing the same direction (use the 25 deg miter on the right side of 0 deg)

- 2 – 1 1/2″ x 3 1/2″ x 26 3/4″ with a 20 deg miter/6 deg bevel cut on each end facing the same direction (use the 20 deg miter on the left side of 0 deg)

Cut Diagram

Build Video

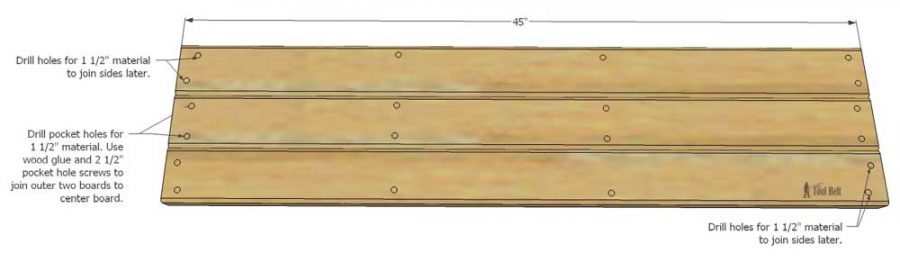

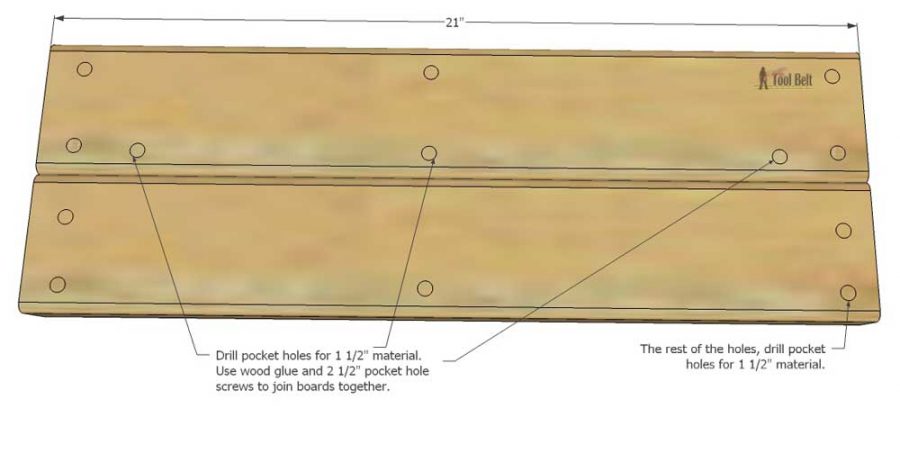

Step 1 – Assemble the Top

Drill pocket holes for 1 1/2″ material in the 45″ 2×4 pieces. Drill pocket holes to join the 3 boards together and also around the edges to secure the sides on later. Use wood glue and 2 1/2″ pocket hole screws to join the 3 – 45″ together.

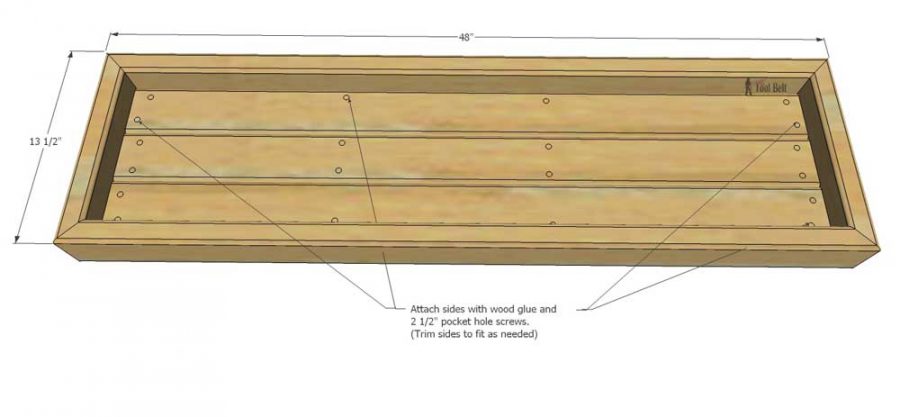

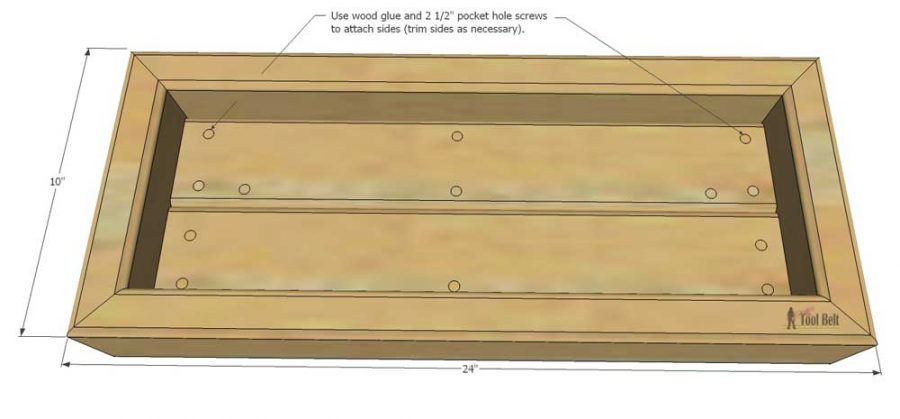

Cut the two 48″ pieces and 13 1/2″ pieces to fit around the 45″ boards. Put the 45″ boards top down and secure the 48″ and 13 1/2″ side boards on with wood glue and 2 1/2″ pocket hole screws. The tops of the side pieces and the 45″ pieces should all be flush.

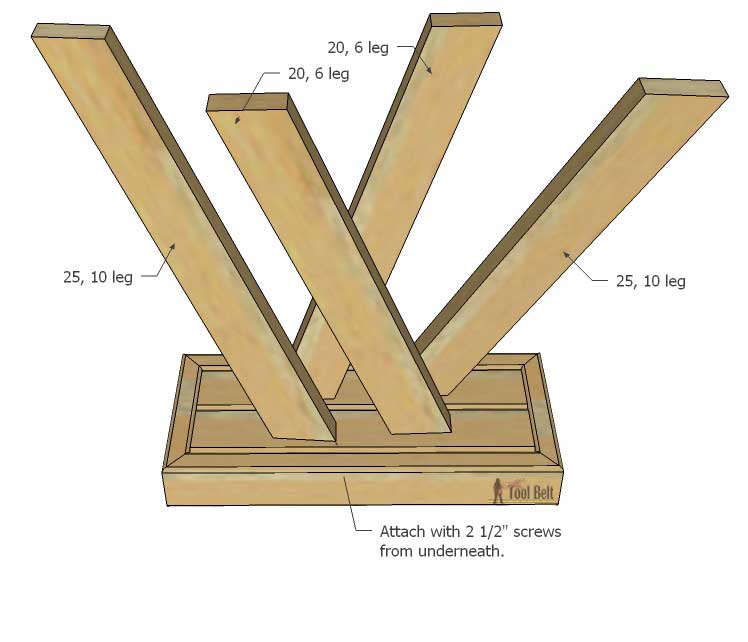

Step 2 – Assemble the Base

Drill pocket holes for 1 1/2″ material in the 21″ 2×4 pieces. Drill pocket holes to join the 2 boards together and also around the edges to secure the sides on later. Use wood glue and 2 1/2″ pocket hole screws to join the 21″ boards together.

Cut the two 24″ pieces and 10″ pieces to fit around the 21″ boards. Put the 21″ boards top down and secure the 24″ and 10″ side boards on with wood glue and 2 1/2″ pocket hole screws. The tops of the side pieces and the 21″ pieces should all be flush.

Step 3 – Sand/Stain

Sand the top and bottom pieces for convenience before putting the legs on.

I’m reviewing the new Ryobi 18V brushless belt sander. When building with structural lumber, you can really save yourself some time using a belt sander to get those boards flat. Going cordless is a little bit frivolous, but it sure is sooo nice and convenient. I only have a few plugs in my garage, I really like grabbing my cordless tools so I don’t have to drag the extension cord everywhere.

This belt sander is super easy to use, but you’ll need to make sure all of your batteries are charged up, because you’ll go through them. It’s a great tool for small to medium builds and doesn’t make you feel like it’s running away with you. There’s also a trigger lock, so you don’t have to hold the trigger down the whole time!

To tighten up the tension on the sanding belt, rotate the knob in the front. (If your sanding belt starts to wander, tighten it up a bit.)

Move the pommel handle by pressing the button and rotating it up or down, so it’s comfortable for you.

If you need to change the belt, loosen the tension and pull the side lever and that’s it.

Belt sanders are made to remove a lot of material, so the grit is usually pretty rough and will leave scratches. If you’re going to stain your table, then follow it up with 120 or finer grit paper with your regular sander. Sand in the direction of the wood grain.

For this finish, I rubbed a light coat of golden oak stain onto the top and bottoms. I used a chip brush and dry brushed (put a little amount of stain on the brush and dab off onto a paper towel) the Kona sparingly onto the top and bottom, focusing mostly on the edges.

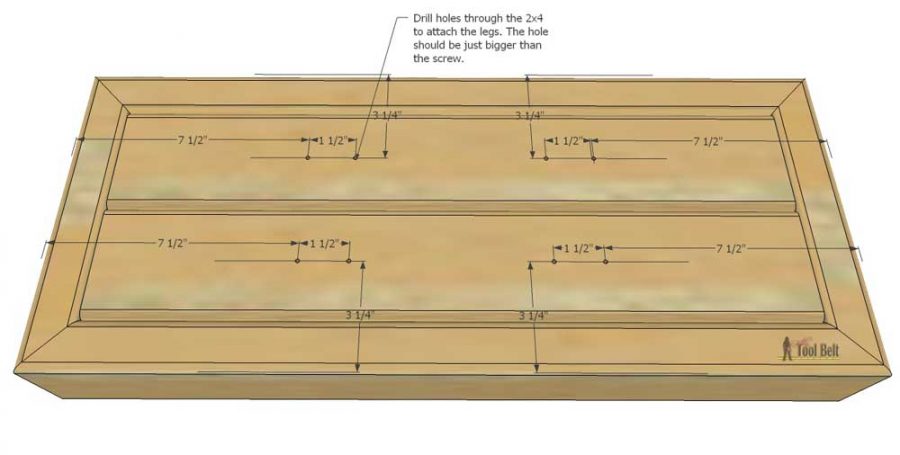

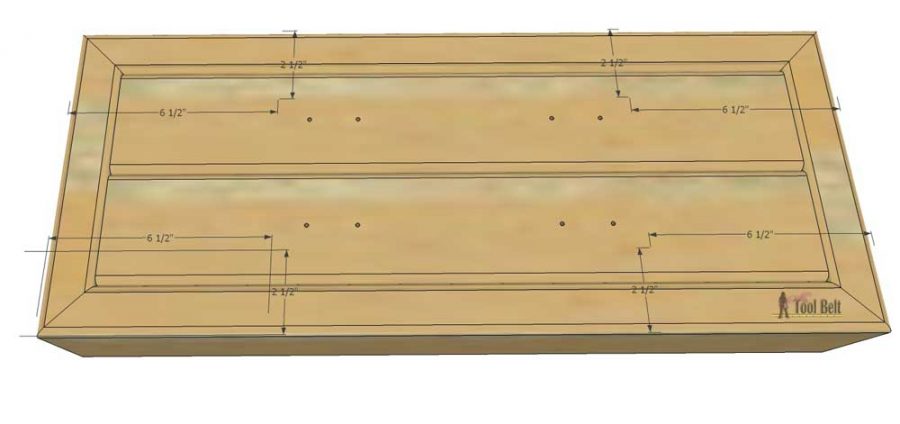

Step 4 – Prep for Assembly

Drill thru holes in the base for the legs. The hole diameter should be just large enough to fit the screw through. Drill 2 holes per leg about 3 1/4″ from the long side and 7 1/2″ & 9″ from the short side.

Mark the outside corner location for each leg.

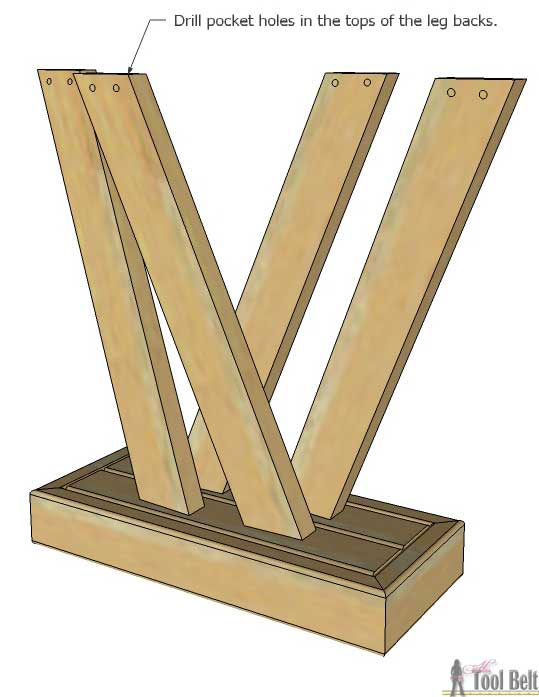

Inspect your legs and decide which one is going where. The 25/10’s will angle outward and go from front/back. The 20/6’s will angle inwards and stay either front or back.

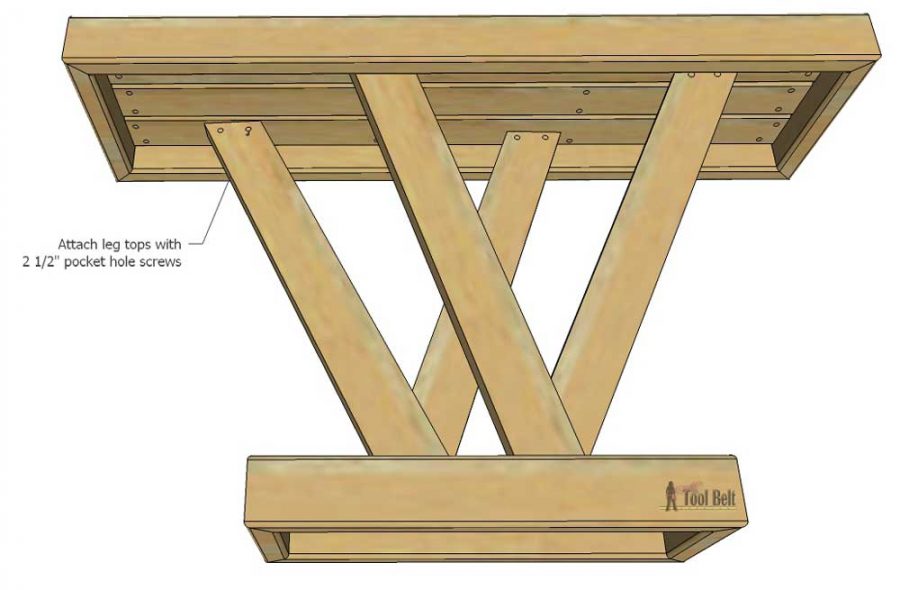

Drill pocket holes in the tops of the legs on the BACKSIDE.

Tip for ORB legs – Sand the legs smooth and apply paint primer, let dry. Lightly sand the dry primer and spray evenly with Oil Rubbed Bronze spray paint and let dry. Spray the corner braces now too.

Step 5

From under the base, attach each leg with a 2 1/2″ screw. Then place the top over the legs and secure the legs with 2 1/2″ pocket hole screws.

Front view of the console table.

Thanks for pinning the 2×4 console table.

Check out all of these fun 2×4 and more projects:

garden arbor | Remodelaholic

15 minute coffee table | The Ugly Duckling House

tiered corner plant stand | Charleston Crafted

single-board rolling bar cart | Woodshop Diaries

outdoor bench w/rope detail | At Charlotte’s House

wall planter and herb garden | Making Joy and Pretty Things

upholstered x-base bench | Frazzled Joy

jumbo tic tac toe | Ginger Snap Crafts

porch bench | Everyday Party Magazine

console table | Hertoolbelt

farmhouse patio table | North Country Nest

easy flower planters | Our House Now a Home

treadmill incline | Practical and Pretty

patio side table | Small Home Soul

You can check out lots of structural lumber builds at the 2×4 and more feature week hosted by Remodelaholic.

“I acknowledge that The Home Depot is partnering with me to participate in the Tool Review Program. As a part of the Program, I am receiving compensation in the form of products and services, for the purpose of promoting The Home Depot. All expressed opinions and experiences are my own words. My post complies with the Word Of Mouth Marketing Association (WOMMA) Ethics Code and applicable Federal Trade Commission guidelines.”

Original article and pictures take www.hertoolbelt.com site

Комментариев нет:

Отправить комментарий